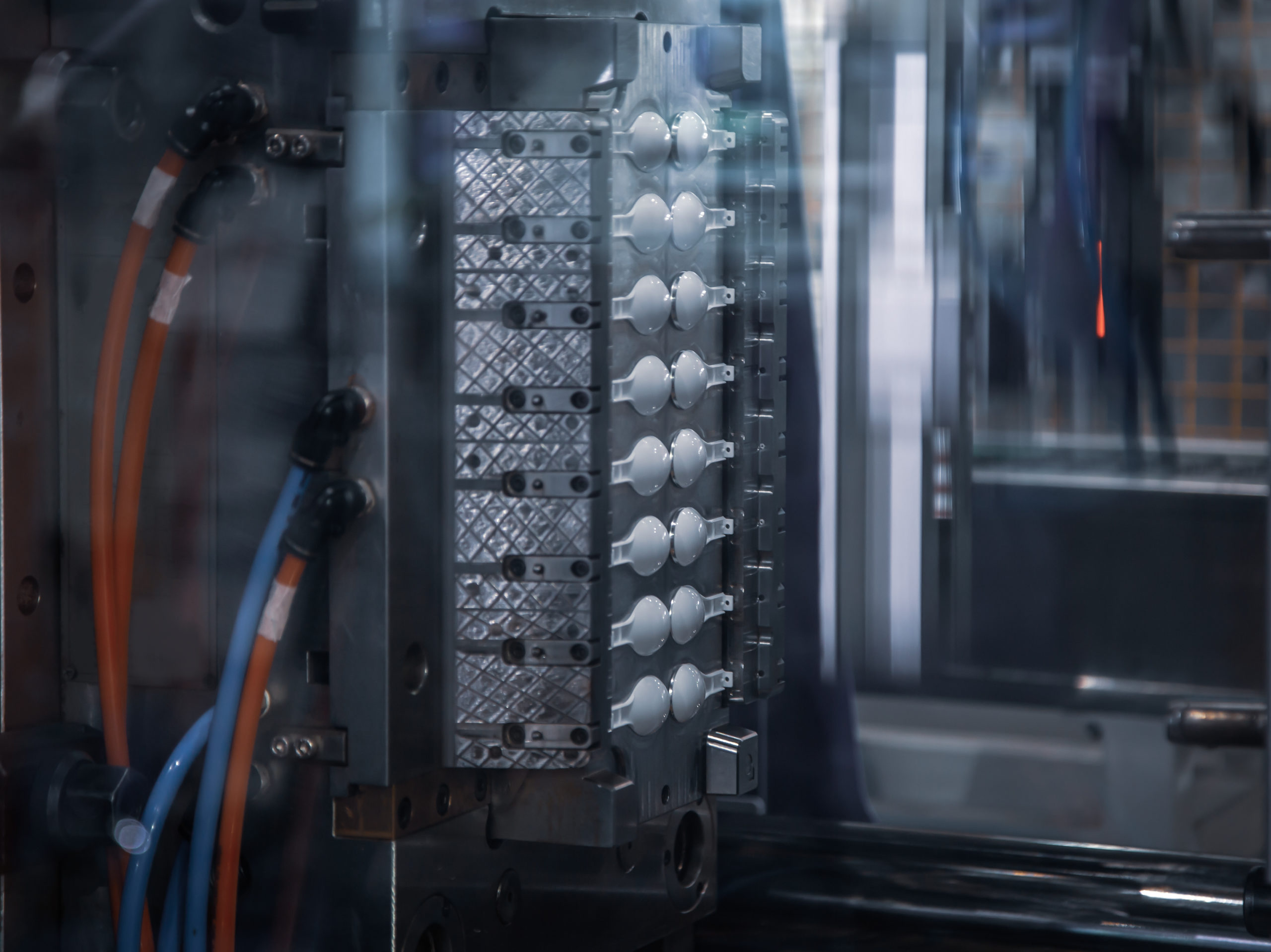

Mold production and service

Injection molds are often complicated technical devices that have to meet many

requirements, withstand high pressures and temperatures, must be stable with precise dimensions and moldings

they must be easily removable from the mold cavity. The design and production is therefore professionally demanding

knowledge, financial costs but also time range.

The cavity of the mold, resp. molding shape, we make using computer programs CAX. First

the component is designed, followed by modeling in a CAD system and then using computer CAM

programs machined on a CNC machine. In addition to these technologies, we use various other technologies, such as

for example, electro-erosive wire cutting or grooving, which make work exceptional

hard and durable materials.

Flowchart of tools

Purchase order

The received purchase order is directed to the production department, where the 3D data of the parts is processed,

their prototyping and their technical specifications.

Mold construction

The production team starts working with the agreed technical documentation of the parts and follows to

making a 3D mold model. Part of our preparations are analyzes of manufacturability, correct performance

mold cavities, deformation and strength analyzes, which we perform through 3D CAD

software. Subsequently, the materials and components for the assembly of the mold according to

design data.

Mold production

The production of the mold takes place after the approval of the design data and production documentation. Production department

makes the production technology and then the CNC programming and the production itself takes place

necessary components, through various technologies such as milling, turning,

electro-erosive machining, grinding, drilling, laser marking, surface treatment and others. Tieto

components are inspected for prescribed tolerances and manufacturing procedures. After making

all parts are followed by their assembly into assemblies, which become a single assembly-form.

Form control

In order for everything to work properly, we thoroughly check and test each form. During the tests

perform tightness checks of cooling circuits, functionality of hot distributions, mold finishing,

functionality of moving parts and control of hydraulic and air elements.

Form export

After passing all the necessary tests, a practical test follows in our OSMOS PLASTICS press, in

which the samples are taken. After successful sampling, the parts are inspected by the quality department according to

approved documentation on 2D and 3D measuring devices and subsequently a measuring protocol is issued.

After its approval by the customer, the mold is prepared for transport together with the complete technical

documentation.