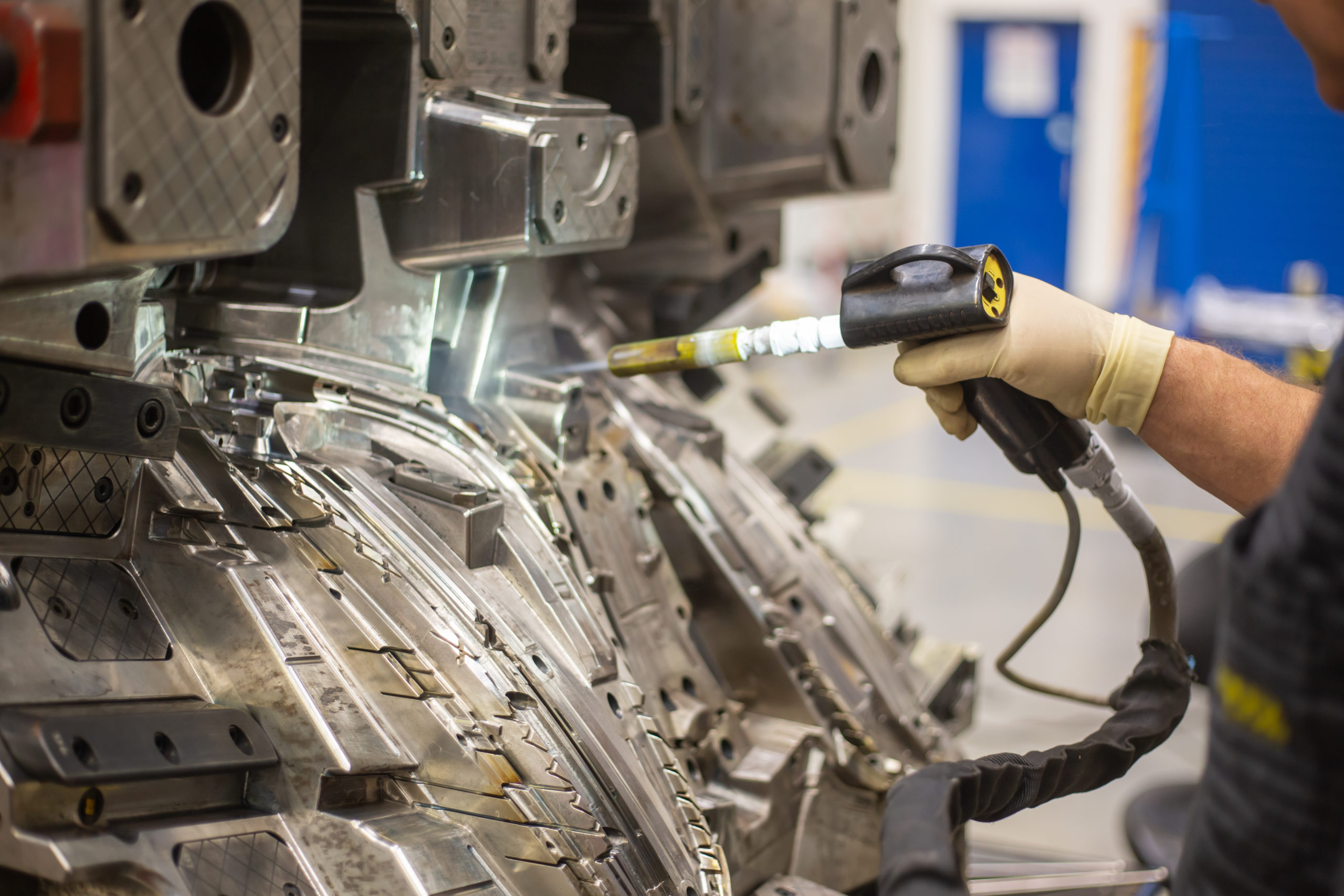

Mold service is an extremely important part of a properly functioning mold. Only regular service

we can prevent the failure. In many cases, service failure occurs

serious damage.

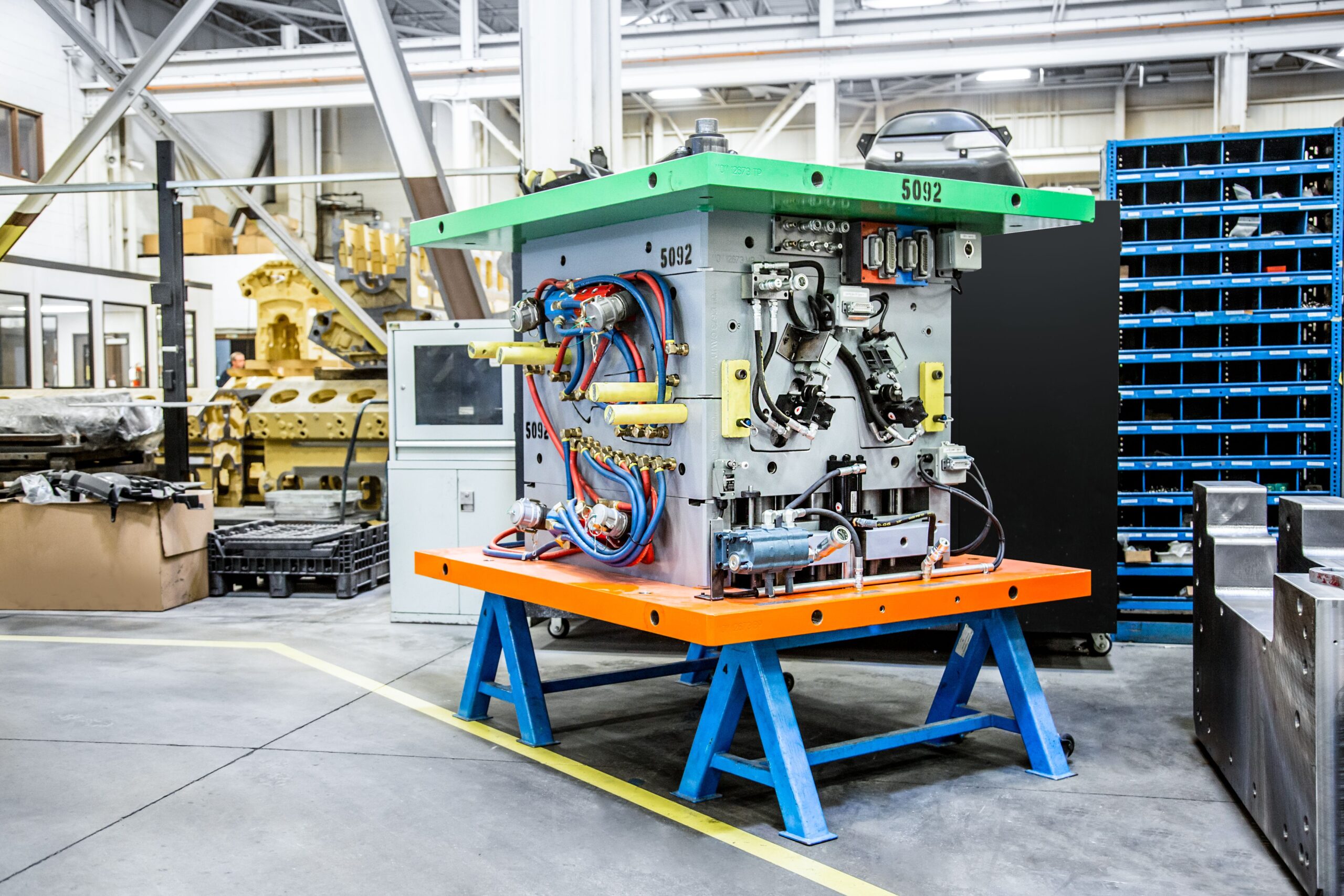

If the molds are regularly maintained, the service life of the tools, their reliability and

cost reduction.

We service molds by trained staff with many years of experience.

During the service of molds, we provide a wide range of operations from the replacement of worn-out o-rings

parts, cleaning of molds from dirt and plastic residues, polishing of mirror surfaces, finishing, repairs

damaged edges, cleaning of cooling ducts or checking for leaks and functionality.

At the same time, we also ensure the control and proper functioning and cleaning of hot systems or replacement

damaged parts. Therefore, do not hesitate to contact us for the proper functioning of your forms.